Product Description

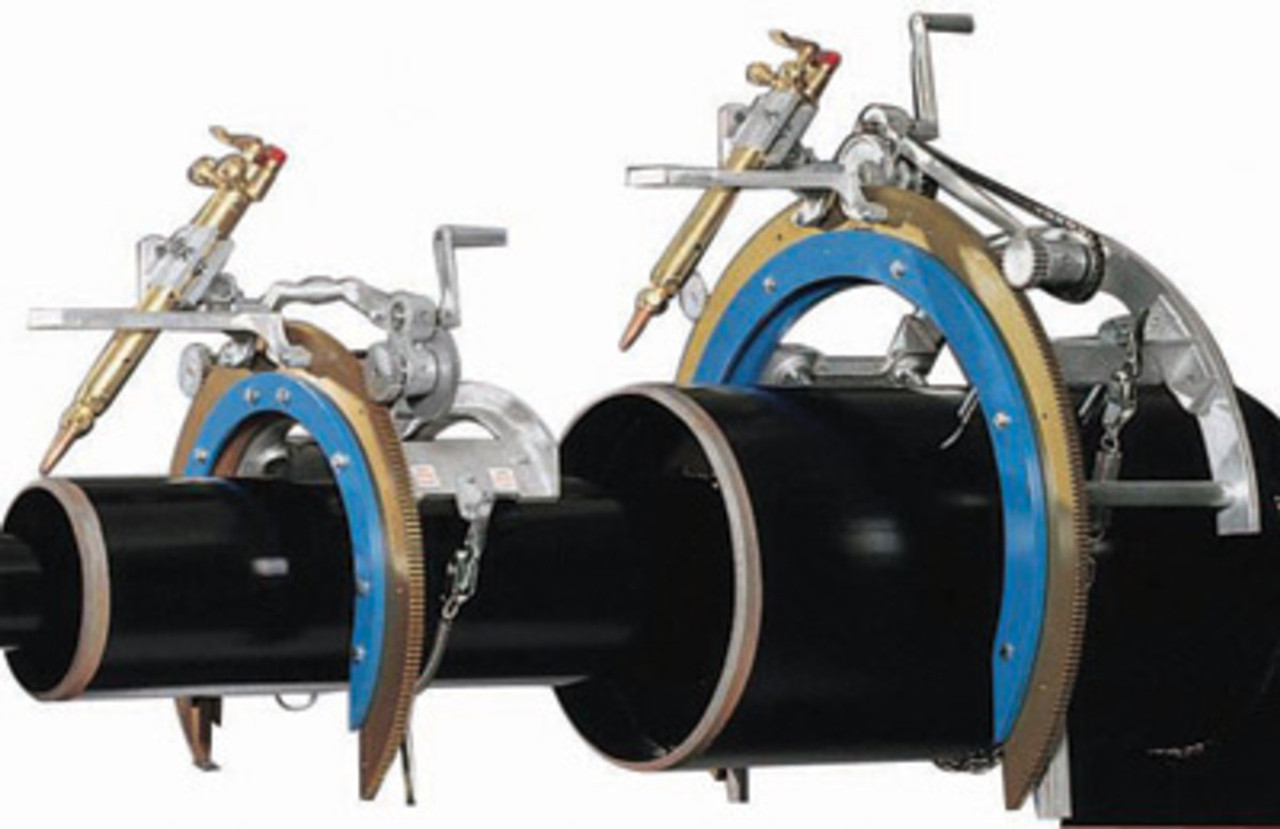

| No. 4 | 20″, 22″, 24″ and 26″ | 81 lbs. (36.74 kgs.) | Std. | Optional |

Std.

|

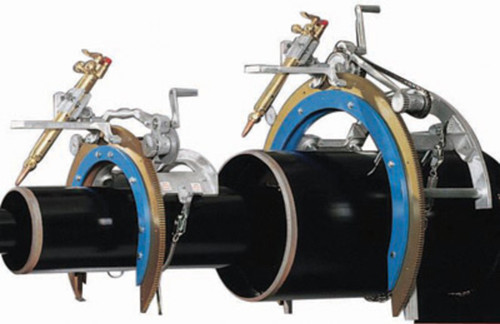

Cuboid Spacer System

H & M’s Cuboid Spacer System relieves frustration and downtime in looking for lost spacers, because the spacers never leave the machine.

The H & M Cuboid is a six-sided form with rectangular sides. Three specific thicknesses conform to different pipe sizes. Only four cuboid spacers are used to quickly set up the machine. In the past 12 spacers were required.

The saddle of each H & M machine and the four cuboid allow four specific pipe sizes to be cut. Each side of every cuboid is clearly stamped to ensure the corrict pipe size. When not in use the cuboid spacers are securely housed on the back of the saddle. It’s a no-lose proposition in time-saving productivity!

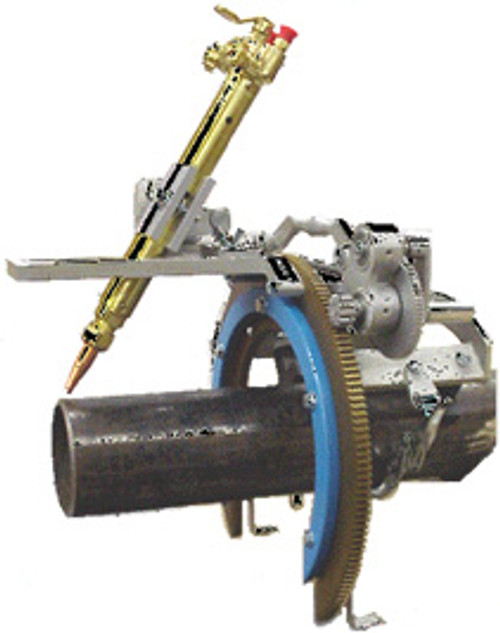

Saddle Design

H & M achieves function and financial advantages for the customer over its competition by designing the precision saddle and ring gear as separate components.

Instead of locating the ring gear in the middle H & M places the saddle behind the ring gear, greatly reducing the risk of warping the saddle while back-beveling.

H & M’s Saddle Assembly is less likely to be damaged; however, if a problem occurs, this seperate component design is more econimical in replacement costs.

7CS Solid Torch Holder

Now standard on all H & M Saddle-Type Beveling Machines, the Adjustable Torch Holder, the Out-of-Round Attachment and all shape cutting attachments, the Solid Torch Holder provides greater cutting accuracy, efficiency and strength. A single thumbscrew secures the torch instead of hose clamps. A cotter pin makes the thumbscrew captive to the torch holder, allowing easy removal or replacement of the torch. Precise and simple to use, the Solid Torch Holder means solid performance.

NOTE: The Solid Torch Holder is available for retrofitting to H & M’s Torch Carrier Assembly. Only two screws are needed for removal and replacement.

2DH Boomer Strap Eye Assembly

Forget cotter pins and S-hooks. H & M offfers a safer, more dependable Boomer Strap Eye on Models 1 and 2 Standard Pipe Beveling Machines. It allows the chain on the boomer assembly to quickly adjust and securely lock the machine to its respective pipe size. The boomer assembly is now a captive member of the machine.

Quality Control

Every H & M machine is manufactured through a rigid system of quality controls, calibrated to ± .025 in concentricity and ± .015 in squareness during final assembly and then re-checked one last time before distribution.

Operation Manual

I. Machine Preparation

- Check to assure the machine is complete and not damaged from shipping. Please notify the distributor where the machine was purchased if a problem exists.

- H&M machines are equipped with the patented Cuboid Spacers to accommodate standard pipe diameters. Special Cuboid Spacer Bolts for all models are available for pipe sizes other than standard (refer to Diagram 1A).

NOTE: If your machine was manufactured before the Cuboid Spacer System was introduced, it utilizes separate spacers for each pipe size. Please call H&M at 918-582-9984 with any questions about upgrading your current equipment.

- Bolt the four Cuboid Spacers under the saddle. Each side of the Cuboid Spacer is stamped with a pipe size. Bolt the Cuboid Spacers on with the pipe size to be cut facing down, making contact with the pipe to be cut. Spacers should be placed perpendicular to minimize contact. (refer to Diagram 1B).

- Attach the standard torch arm and torch holder assembly, or the optional Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment securely to the ring gear.

- Position and secure a two-hose machine cutting torch in the torch holder. No pitch rack is required. The two-hose machine cutting torch should have an overall length of 15″ to 16″, or it will not reach the machine’s smallest pipe capacity on a 37.5-degree bevel angle.

Store the Cuboids on the back of the saddle (refer to Diagram 1C).

II. Positioning On Pipe

- Place the machine on the pipe to be cut. Adjust the boomer assembly by lengthening or shortening the boomer chain until the machine is securely attached to the pipe.

- Set the torch to the desired degree of bevel angle by loosening the appropriate wing nuts on the standard torch holder. Position the torch to the desired bevel angle. Make sure to tighten the wing nuts securely after setting the bevel angle.

A. If using a Model “C” Adjustable Torch Holder or a Model “C” Out-of-Round Attachment, the bevel angle is set by loosening the “T” handle. See the operation manual for the Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment for detailed instructions.

- Vertical adjustment with a standard torch holder is achieved by loosening the thumbscrew on the torch holder and adjusting the torch tip to approximately 1/4″ from the pipe.

A. The setting for the Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment is obtained by turning the proper knob. See the operation manual for the Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment for detailed instructions.

- Horizontal adjustment with a standard torch holder is accomplished by loosening the appropriate wing nut on the torch holder, manually positioning the torch tip to the intended line of cut and securely tightening the wing nut.

A. The setting for the Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment is obtained by turning the proper knob. See the operation manual for the Model “C” Adjustable Torch Holder or the Model “C” Out-of-Round Attachment for detailed instructions.

- The standard beveling machines are manually driven. The operator turns the crank handle, generating travel to the torch during the cutting process.

- For motorized machines set the speed control to a LOW setting. Plug into a 110- to 120-volt AC power source and check the power. If the power source is 220 volts the machine will be supplied with a 240/120 transformer.

- Light the torch and adjust to a neutral flame. When the metal has reached a proper temperature turn the high-pressure oxygen valve to the OPEN position, then start the cutting process. Start rotating the ring gear either manually or with an electric travel motor.

NOTE: If you are unfamiliar with the safe operation of an oxy-fuel cutting torch, ask your local welding distributor for training before using this equipment. - When the cut has been completed turn off the cutting oxygen and remove the machine from the pipe by releasing the boomer assembly.

III. Elimination Of The Blow Hole

- Eliminating the blow hole can be accomplished when using the standard torch holder. The standard torch holder has a knurled knob (Part No. 7F) located on the right side of the torch holder. This knob will tilt the torch up about 3 to 5 degrees from the cut line when the knob is turned. This position allows for the preheating and piercing of the pipe. After the pipe has been pierced the knurled knob is turned again returning the torch to its original position over the intended cut line and leaving the blow hole located on the scrap end.

NOTE: If using a Model “C” Adjustable Torch Holder or a Model “C” Out-of-Round Attachment, see the appropriate operation manual.

IV. Back-Beveling Procedure

Back-beveling, cutting a bevel toward the machine, can be accomplished in several ways:

- When using a standard torch holder the only requirement is loosening the wing nut which secures the torch holder to the torch arm. remove the torch holder, rotate it 180 degrees and secure it to the torch arm. The torch is now reversed and angled back toward the machine.

- Back-beveling can also be achieved by using and angle head attachment on the cutting torch. An angle head attachment allows the cutting tip to be positioned to different bevel angles independent of the torch. The torch remains vertical and the angle head attachment pivots the cutting tip to different angles.

- If back-bevelin using a Model “C” Adjustable Torch Holder or a Model “C” Out-of-Round Attachment, set the desired degree of bevel angle on the protractor by loosening knob #3. Set the machine on the pipe as in normal cutting procedures and begin the back-beveling operation. See detailed instructions in the appropriate operation manual.

WARNING: Position the cutting tip as far back from the ring gear as possible when. Excess heat placed on the ring gear during back-beveling can damage the machine.